HM136MAX™ Bundles

Product Features

WIDE-CAPACITY FULLCUT™ SAWHEAD

The HM136MAX™ features our FULLCUT™ sawhead, which matches a 36” (91 cm) diameter log capacity with a 36” (91 cm) cut width. The FULLCUT™ sawhead unlocks the full potential of your logs by keeping their widest assets intact. So you can create stunning high-value live edge boards with unmatched efficiency.

INDUSTRY-LEADING POWER SOURCE

The HM136MAX™ is powered by the reliable 21 HP Honda GX630 V-twin engine. With racing-inspired technology, the GX630 is smooth and exceptionally quiet. Our engineering team worked with Honda to ensure that their engine and our sawmill were a match set, both for the workload that needs to be done and the conditions we're asking it to work in.

HEAVY-DUTY 4-POST CARRIAGE ASSEMBLY

Our heavy-duty 4-post head design is reinforced with a laser-cut welded back beam and top tubular crossbeam providing superior structure to the sawhead. The assembly is anchored between our precision laser-cut carriage side plates, to provide exceptional rigidity, and ensure smooth, accurate cuts.

GAS AND GO AUTO LUBE SYSTEM

Every one of our sawmills features a gas and go auto lube system. This means the throttle handle engages the engine RPM, saw blade, and patented auto lube system simultaneously. This system makes the process of cutting lumber quick and efficient and reduces the number of steps required by the operator.

ALUMINUM LUBRICANT TANK

Our sawmills are equipped with a weather-resistant aluminum lubricant tank, ensuring long-lasting performance in the most adverse conditions. The tank's needle valve allows precise control over the flow to the auto lube valve, enabling fine-tuning as needed.

CONSTANT-PRESSURE SAWHEAD U-BUSHINGS

We’ve designed a unique constant-pressure U-bushing that facilitates a positive connection between the sawhead and the carriage posts while allowing the sawhead to move up and down smoothly. The U-bushings are constructed from glass-filled nylon, giving them a long service life.

RAPIDCHANGE® BLADE SYSTEM

The RapidChange® blade system is exclusive to Woodland Mills. RapidChange® is a tool-less approach for changing blades quickly that reduces the need for blade tracking adjustments between blade changes. Stacked Belleville washers act as a shock absorber for the blade while giving consistent blade tension in all temperatures, ensuring less stress on the blades.

DUAL RACE BEARING CARRIAGE WHEELS

The sawhead's carriage wheels have a dual race bearing. This provides the best connection between the rolling wheel and the track surface, to ensure stability from the wheels to the track to the sawhead. The radius profile in the groove and the square-topped tracks are designed to wear together to make a matched set over time. To keep the track free from debris, stainless steel wire sweepers clean the track while in use.

PRE-ASSEMBLED SAWHEAD

To reduce your assembly time, we carefully pre-assemble key components of the sawhead. Having the advantage of pre-assembled parts help you get up and running faster, saving you valuable time.

COMPREHENSIVE LOG SCALE

Two magnetic scales provide multiple preset board-thickness settings with built-in kerf allowances for consistent, accurate cuts ranging from 3/4" to 4" thick. The scales help you track blade height off the deck for precise board and cant sizing. Made from durable, UV-protected vinyl with strong magnetic backing for a secure hold and clear visibility in all conditions.

POWDER-COATED STEEL BLADE GUARDS

Our blade guards are built with durable, powder-coated metal for resilience and longevity. For added convenience during sawhead maintenance or blade changes, the guards are side hinged, allowing them to easily move out of the way and provide unobstructed access.

ADJUSTABLE THROTTLE CONFIGURATION

Our adjustable throttle assembly offers complete customization for individual needs. You can position both the throttle and push handle according to your preference based on track height, ensuring a comfortable operating experience.

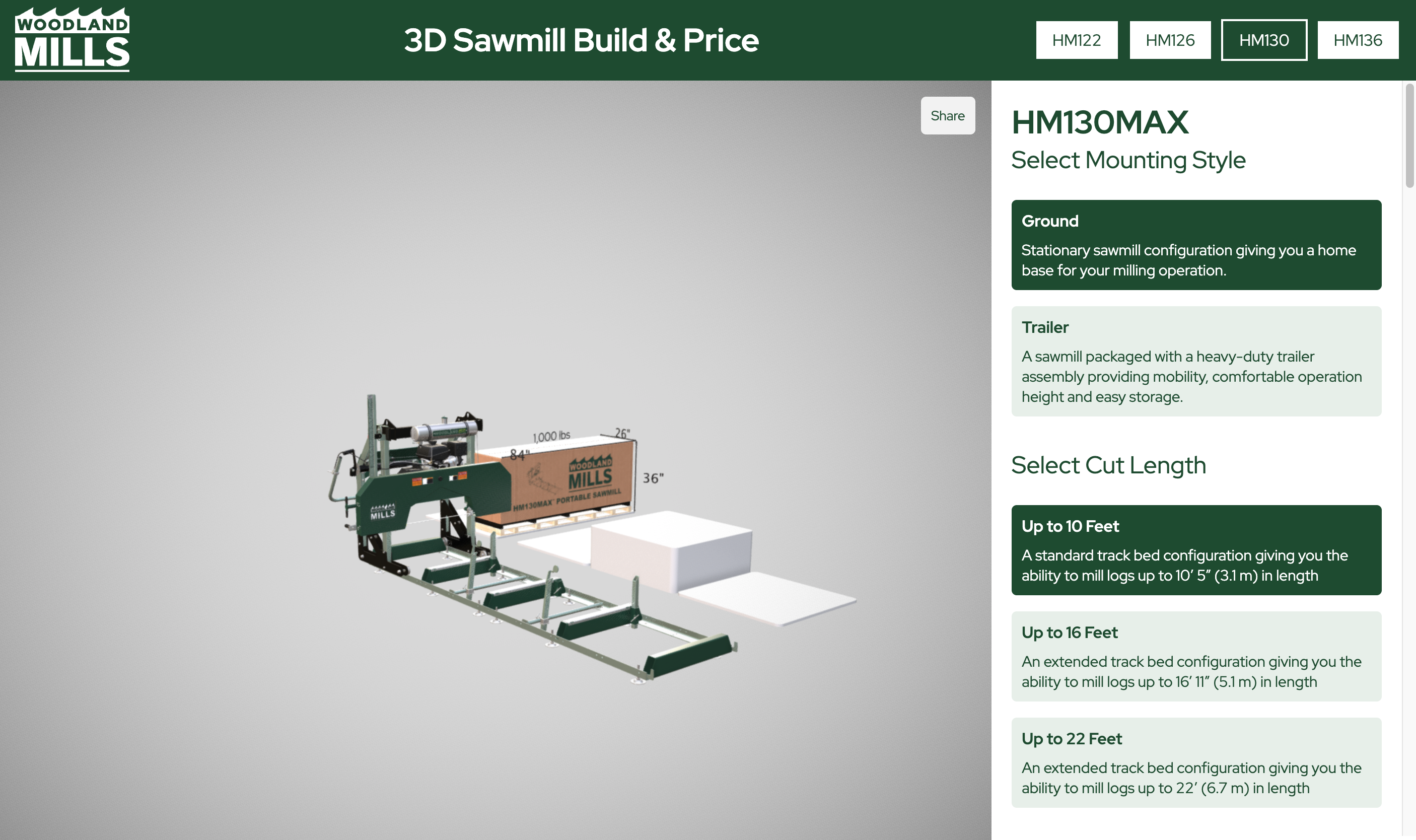

PRECISION TRACK SYSTEM

The HM136MAX™ uses rigid 2 3/8″ x 4″ (6 cm x 10 cm) L-rails with precision-machined tops to support smooth, accurate sawhead travel. These rails are cross supported with heavy-duty 2 3/8″ x 4 3/4″ (6 cm x 12 cm) rectangular log bunks. These cross supports ensure the weight of the log is dispersed over a large bearing surface to avoid marking the log with indentation and provide additional rigidity to the track system.

The track itself consists of two 6’ 5” (1.95 m) sections allowing for 10’ 5” (3.1 m) log lengths. Additional 6’ 5” (1.95 m) tracks can be attached to accommodate logs of any length.

RELIABLE LOG SECURING

The HM136MAX™ features a simple adjustable quick lock log clamp to securely hold the log while milling. It also includes two short log supports and two roller-top supports, making it easier to roll and position logs on your tracks. The track itself consists of two 6’ 5” (1.95 m) sections allowing for 10’ 5” (3.1 m) log lengths. Additional 6’ 5” (1.95 m) tracks can be attached to accommodate logs of any length.

EXPANDABLE TRACK SYSTEM

Our mills are designed to cut logs up to 10' 5" (3.1 m) long using the standard track configuration. You can unlock unlimited length potential by adding optional 6' 5" (1.95 m) track extensions. These extensions come with an extra log clamp assembly, roller top log support, and required bunks, allowing you to customize the cutting length to your specific requirements.

GO MOBILE WITH WOODLANDER® TRAILER PACKAGE

Move your HM136MAX™ between locations with the Woodlander® trailer. Packaged together, the HM136MAX™ Woodlander® trailer gives you a better working height and provides you with mobility to bring the sawmill to different work sites or easily move it into storage. Levelling jacks are provided so you can quickly level the trailer and tracks when deployed.

AUTO-LOCKING ADJUSTABLE BLADE GUIDE

The premium Auto-Locking Adjustable Blade Guide is constructed using stainless steel V-rollers and a matched machined aluminum arm to keep guides close to the wood being cut and reduce blade wander.

AUTO-LOCKING SAWHEAD

The auto-locking sawhead ensures precise and consistent control. Simply push the handle in and rotate through 16 locking locations to move the sawhead up or down. Coupled with an Acme lead screw, you’ll get precise adjustments accurate to within 1/64”. Traditional magnetic log scale rulers are also included to line up precision cuts.