What is a Board Foot? Explaining the Board Feet of Your Lumber

Calculating board feet is an important step to figuring out the total volume of your rough lumber

How many board feet are in your lumber? Board foot calculation is a popular way of figuring out the volume of your boards in North America and Europe and many sawyers use it every day.

Since it takes into account the thickness of your boards, it's a more accurate measurement of the actual quantity of your wood as opposed to just measuring the square footage.

But how do you do it? Let's find out.

What does the term "board foot" mean?

A board foot is a term used to describe the dimensions of a piece of lumber, utilizing the length, width and thickness. It can be abbreviated as FBM for "foot, board measure." It is also sometimes written as "bd. ft."

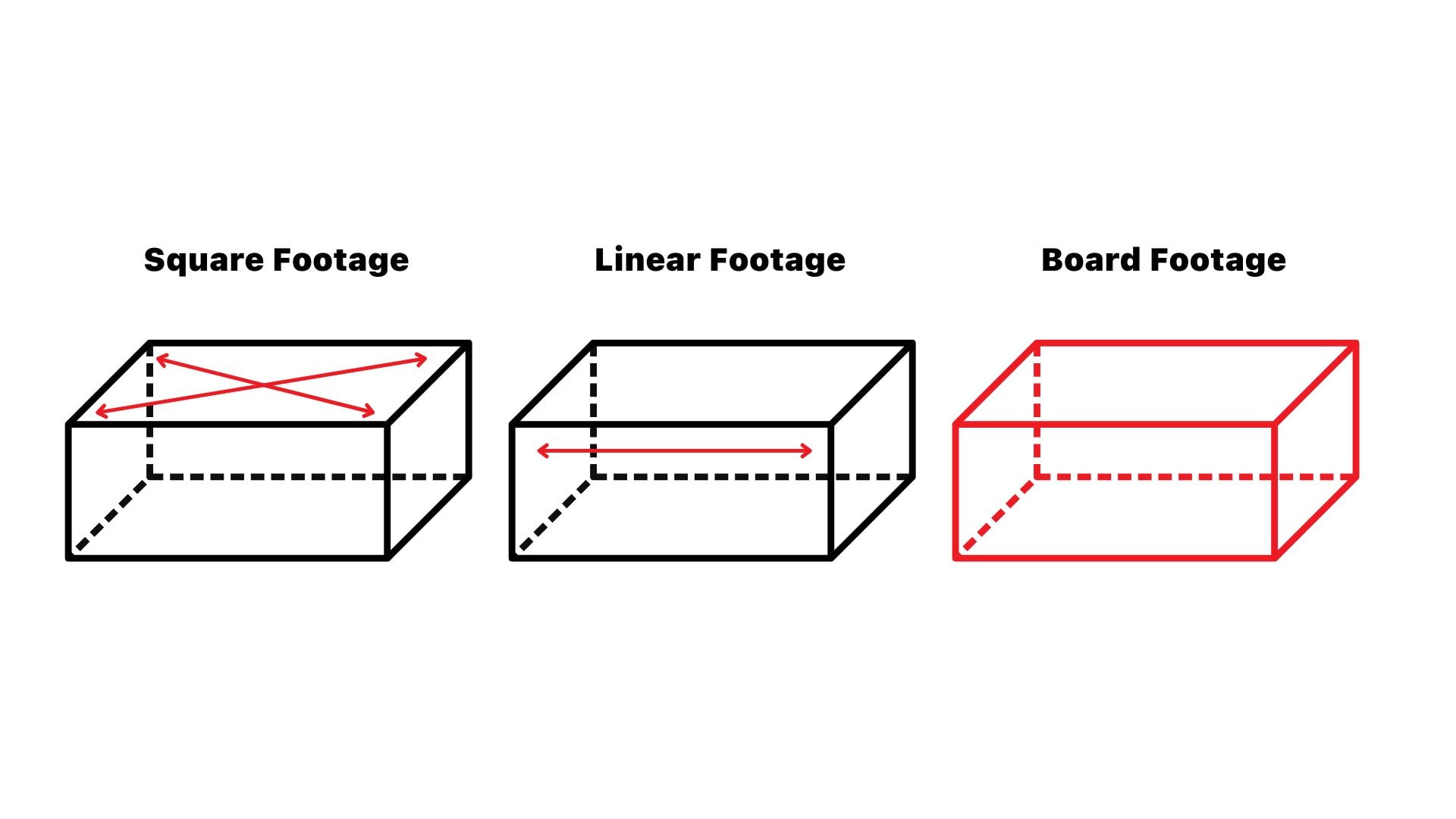

Here are some common measurements and how they differ from board feet:

-

-

Square Feet: This is used to describe the surface area of a flat object, and is calculated by measuring the length and width. One square foot would be 1' x 1'

-

Linear Feet: This accounts for just the length of an object. So something with a length of one linear foot is 12 inches long.

-

Board Feet: This combines the actual width and length with the thickness. That means it takes into account the volume of the board. One board foot is measured as 1' x 1' x 1".

-

This is helpful when pricing out lumber, since two boards could be 4x8" but if one has a one inch thickness and the other has a two inch thickness, the board footage of one would be greater than the other, giving it a higher volume.

How do you calculate board footage?

The best formula for calculating board feet is to multiply the thickness x length x width then divide that by 12.

When calculating you would write it as: "(Length x Width X Thickness) ÷ 12 = Total Board Footage."

How do I figure out my own board footage?

Once you have the calculation ready, doing the math with a calculator or your phone is easy.

If you have a board that is:

-

-

8" long

-

4" wide

-

2" thick

-

You would calculate that as: (8 x 4 x 2) ÷ 12, giving you a board footage of 5.33 FBM.

Meanwhile a board that is:

-

-

24" long

-

2" wide

-

1" thick

-

Would be calculated as: (24 x 2 x 1) ÷ 12, resulting in a board footage of 4 FBM.

How does board footage apply to dimensional lumber?

Board feet are often used when pricing lumber, to quickly calculate the actual volume of wood. This is useful since it can often be difficult to visually gauge the actual size of two different boards if they are different lengths, widths or thicknesses. A board with a larger board footage is, most of the time, priced higher than a smaller board of the same species and quality.

But the material does factor into the cost, as a rarer or more exotic species have a higher cost per board foot. Sometimes too the quality of the lumber, such as if it's knotty or warped, will impact the price per board foot too.

For example, if you're making a table and need a slab of oak wood, you might charge $5/board foot. But if the wood is poor quality, you may charge less. More exotic species like black walnut can sell for upwards of $20 per board foot.

What should I charge per board foot for my lumber?

Here is what you should do to calculate the value of your wood:

-

-

Look at local board foot prices for your species

-

Calculate the board feet of your lumber pile

-

Come up with a rough quote of the value of your lumber

-

Adjust it based on the quality of the lumber

-

Another thing to factor in is that lumber is worth more dry than it is wet, as it means your customers don't have to wait for the materials to dry to work with them. Because most sawyers calculate board footage at the end when their lumber is dry and has shrunk, it's worthwhile to remember that wet, green lumber is often worth less per board foot.

SHOP SAWMILLS

HM122

An entry-level sawmill packed with impressive features at a budget-friendly price. Designed for hobby sawyers or woodworkers looking for an economical solution to mill lumber.

HM126

One of the best-valued sawmills in the industry. A longstanding favourite that ensures smooth, accurate cuts. Perfect for hobby sawyers, entrepreneurs or seasoned woodworkers.

HM130MAX®

A wide capacity sawmill that produces stunning high-value live-edge boards. Loaded with features including our FULLCUT™ sawhead, RapidChange® blade system, auto lube, and more.

HM136MAX™

The ultimate solution for cutting wide live edge slabs, perfect for tabletops, counters, benches, and more. Our unique FULLCUT™ sawhead design ensures your logs' widest assets are left intact.

Join the Woodland Mills Community Facebook group. Search advice and insights from over 65,000 knowledgeable, supportive members.

- Pre-purchase considerations

- Sawmill set-up support

- Project inspiration photos and videos

- Community troubleshooting support