How to Avoid Hitting your log stops

Many sawyers "join the club" by accidentally hitting their log supports with their blade, but here's an easy way to avoid it

It's a problem as old as time. You've been milling wood on your Woodland Mills Portable Sawmill, when you accidentally saw into your log supports.

Maybe you just barely touched it and damaged some teeth on your bandsaw blade. Or maybe you fully cut the top of it off, ruining your blade and damaging your log support.

It happens pretty often. Just look at the Woodland Mills Product Owners and Community Facebook Page and you'll find plenty of sawyers who have "joined the club."

Some sawyers say they've "chewed up blades," like Jason, by hitting their log supports while milling. Unfortunately when you hit metal, the blades are often damaged beyond repair, requiring replacement.

What's happening?

So what's causing people to mill their log supports when they're supposed to be milling lumber?

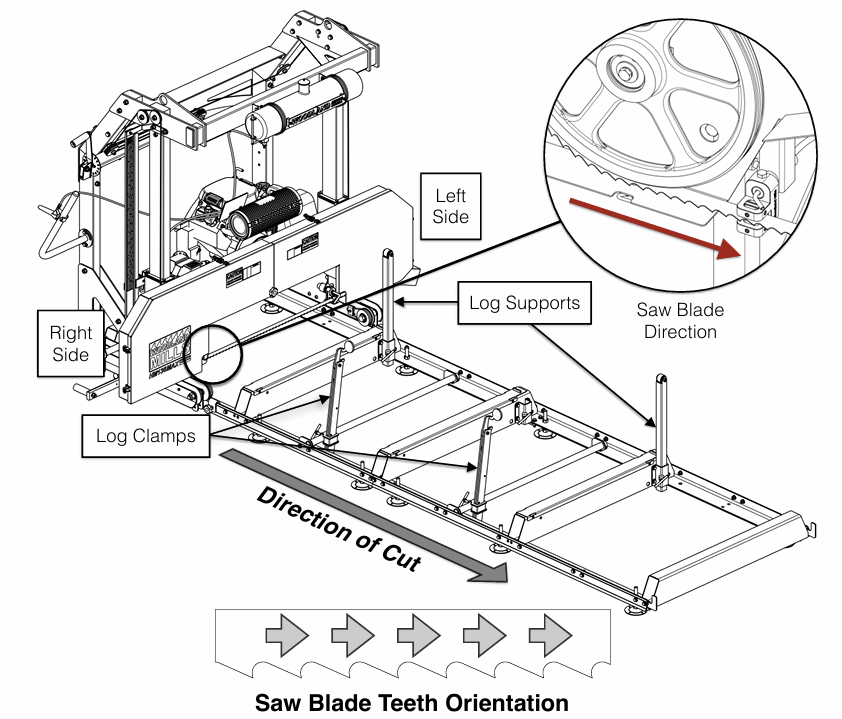

As detailed in your sawmill's manual, the log supports are used to hold the log straight during operation.

The log supports sit on one side of the mill (the left side in the illustration below) opposite the operator, and are adjustable. These are what you use to straighten your log, as they sit with the bunks at a 90 degree angle when your mill is straight and level.

The log clamps are positioned on the same side as the operator (the right side), and are used to clamp the log in place, putting pressure on the log so it's pressed up against the log supports.

Many sawyers, when milling, will sometimes cut into their log supports if they're positioned too high. While some will stop the second they feel resistance and only do a little bit of damage, others power through and cut top of their log support off.

Properly placing your log supports

Part of the milling process means that between cuts, when repositioning your log, you're reviewing the height of your log stops. If you're lowering your sawmill head, you should also be lowering your log supports to avoid hitting them.

It takes time and it's an easy step to forget, but oftentimes just a little bit of caution goes a long way towards saving your blades.

You should ideally have your log supports at least an inch beneath where your blade will be cutting. Your log shouldn't be moving while cutting, but if it does, that extra room will ensure your log stops remain safe.

Where it gets dicey is when you're making the last few cuts on a cant, and you may only have a few inches left of log to cut. That doesn't leave you a lot of room for your log supports and log clamps to work, so smart placement of them is crucially important.

You may want to bend down and visually inspect the track from behind the sawhead, so you can better see from the blade's perspective whether you're at risk of hitting your log supports.

Use your blade stopper

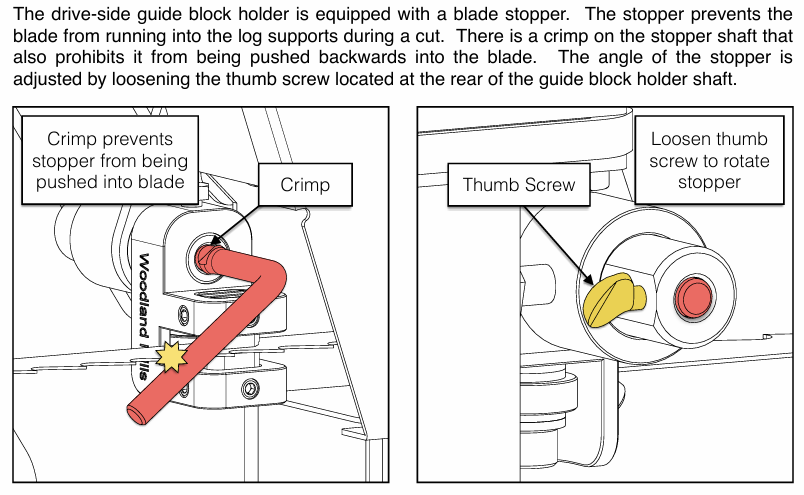

Did you know there's a part on your sawmill specifically designed to prevent your blade from making contact with your log supports?

The blade stopper is located on the saw head, on the opposite side from the operator. When used properly, the blade stopper connects with your log stops, stopping the mill before your blade can make contact with them and damage your blades.

Before starting your mill and making a cut:

-

-

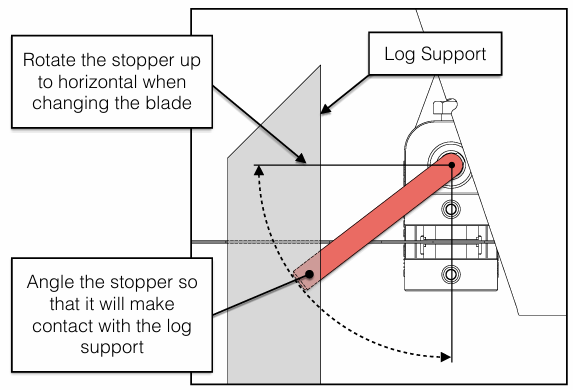

Use the thumb screw to loosen the blade stopper

-

Place the blade stopper handle at an angle so it would connect with the log stop if the stop is placed too high

-

When changing blades, rotate the blade stopper so it is horizontal to get it out of the way, just remember to orient it back when you're done so it continues to serve its purpose

-

Thanks to your blade stopper, you should see a difference in the amount of times you cut into your log stops and it will save you money from having to buy replacement blades.

Homebrew solutions

Some sawyers will install their own solutions on their mills to avoid hitting their log stops.

Some install wooden extensions which fit into the existing log stops, that way if you cut into them, it won't damage the blade. The downside to this is that the sawmill was designed with steel log support in mind, and it may affect the stability of your log.

Other sawyers have created parts which fit inside the log support which collide with the sawhead so you won't accidentally meet the blade. While this may seem helpful, the blade stopper serves an identical purpose and is a standard feature on all Woodland Mills portable sawmills.

Depending on how you want to tackle it, you can definitely utilize a DIY solution which fits into the existing log stop without modifying the sawmill itself, but one of the best solutions you can do, as plain as it may be, is just to show the right amount of caution when you're milling.

Simply remember to set aside the time while milling to:

-

-

Check your log stops before making a cut

-

Review your log stops after adjusting your log or cant

-

Position them low enough and with enough room that you won't risk hitting them with your blade

-

If you're still struggling, bend down and look at your sawmill track from behind your blade, to see whether your log stops are in the way

-

Do this and you should be able to keep your log supports safe, save money on blades and continue milling and making lumber for all your projects.

SHOP TRAILER MOUNTED SAWMILLS

HM122

The HM122 portable sawmill, packaged with the rugged Bushlander® trailer for complete mobility, loaded with features like the RapidChange® blade system, auto lube and more.

HM126

The sawyer favourite HM126 portable sawmill, packaged with the Woodlander® trailer for complete mobility, ideal operation height and easy storage.

HM130MAX®

The wide capacity HM130MAX® portable sawmill, packaged with the Woodlander® trailer for complete mobility, comfortable operation height and easy storage.

HM136MAX™

Our widest-capacity portable sawmill, the HM136MAX™, packaged with the Woodlander® trailer to make it easy to take anywhere and easy to store.

Join the Woodland Mills Community Facebook group. Search advice and insights from over 65,000 knowledgeable, supportive members.

- Pre-purchase considerations

- Sawmill set-up support

- Project inspiration photos and videos

- Community troubleshooting support