A Breakdown of Portable Sawmill Running Costs

Want to know the operational costs of running a portable sawmill? Here's everything you need to know

A portable sawmill is a powerful lumber-making tool, but it's important to know the costs associated with it too.

Woodland Mills engineers our portable sawmills to be easy to maintain, meaning you don't have to stress over maintenance so downtime is minimized and you can instead spend your time milling your own lumber.

There are a few maintenance points, consumable wear points and components that you will need to pay attention to over time which could make up the running costs on your mill.

Whether you're a part-time woodworker or run your own portable sawmill business, knowing your costs can be critical, so let's lay down all the expenses you should know about when running your sawmill.

Engine Maintenance

The main maintenance point on your portable sawmill will be your engine.

The two main running costs for your maintenance will include:

-

-

Engine oil

-

Fuel

-

The type of engine oil required will be listed in the engine manual. You should top up your fuel tank before each time you run your sawmill so you don't run out midway through milling.

While the cost of oil and gas will depend on where you live, these make up the main running costs of your mill.

Blades

Sawmill blades make up another core part of your portable sawmill's running costs. Blade costs depend on how many you buy and where you buy them from. Depending on the model of sawmill, Woodland Mills' sawmill blades come in sets of 5, 10 and 15.

While it will depend on the size of the blade, expect typical standard bandsaw blades to cost you an average of about $18 to $30 per blade. Blade longevity is greatly dependent on the species of wood and condition it's in. A good rule of thumb is to refresh or replace your blades after approximately two hours of actively cutting wood.

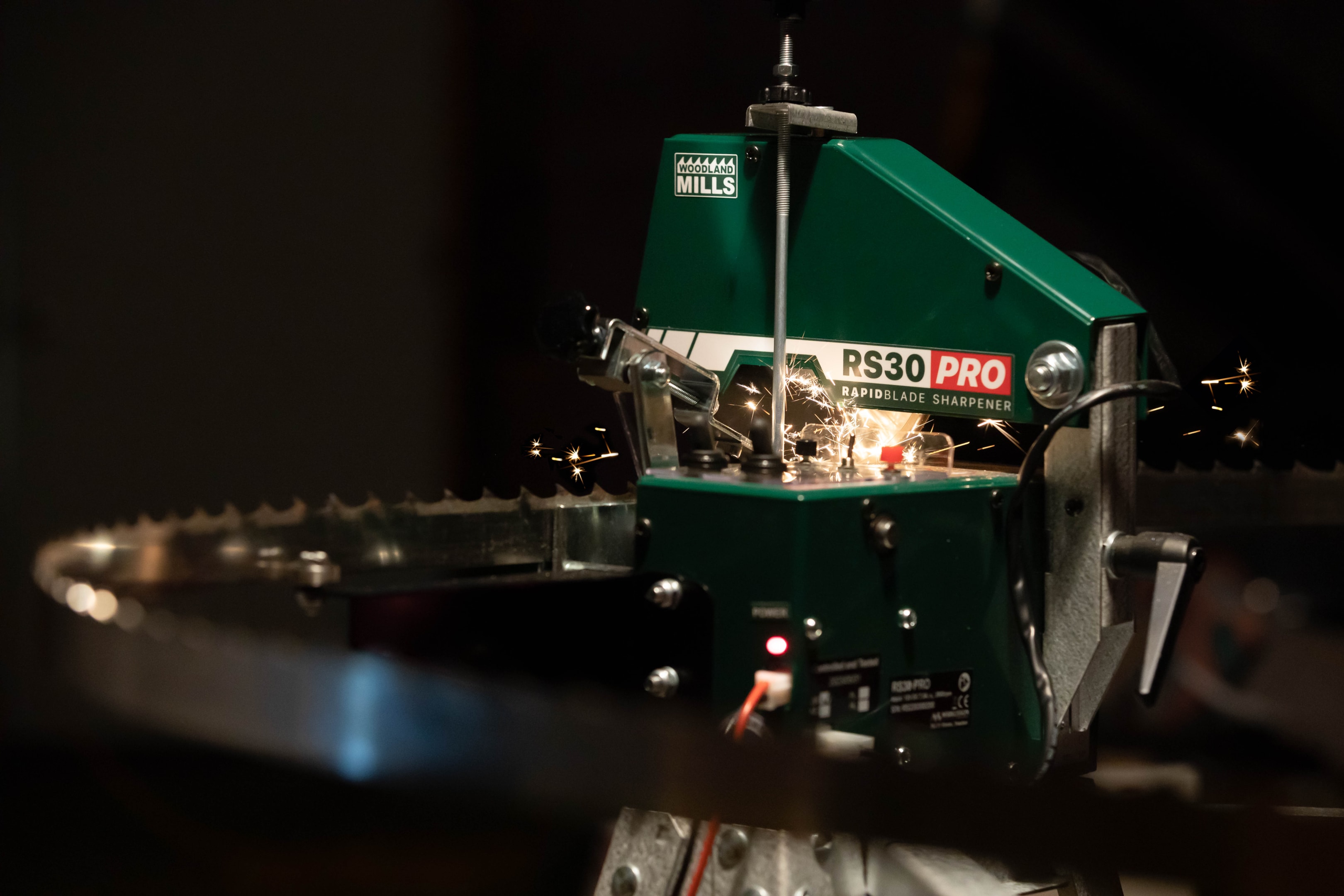

Remember: Consider getting a blade sharpener like the RS8 or the RS30 PRO. These can help extend the life of your blades, sharpening them up to five times to keep them in service longer and save you money.

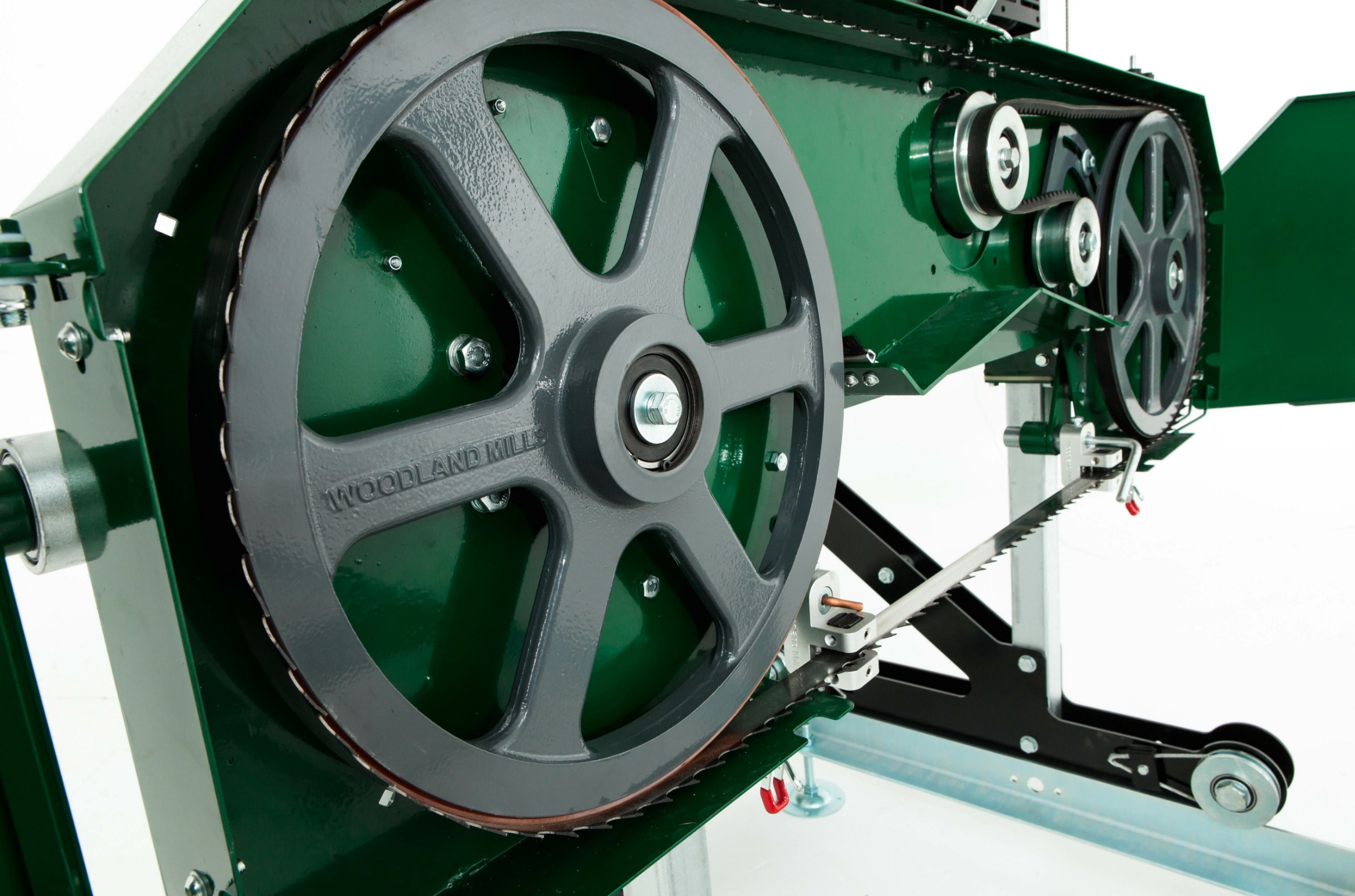

Belts and Bearings

When it comes to internal components of your sawmill you may need to replace the belts and bearings of your sawmill over time.

These are considered wear points, so monitor their condition and prepare replacement when it looks like they're starting to show signs of wear.

The Woodland Mills Sawmill Maintenance Kit provides multiple replacement parts for key wear components like this, so you can use that to prepare and avoid maintenance downtime. Spending a little money now saves you a ton of time later, which in effect helps save money down the road.

Portable Sawmill Business Expenses

Are you planning on running your mill for a sawing business? If so, keep close track of your maintenance expenses. Depending on your area and whether you're operating your sawmill business as a self-employed venture you may be able to expense these on your taxes at the end of the year.

Remember to:

-

-

Keep track of all the business expenses you collect throughout the year

-

Keep receipts or invoices for any purchases

-

Track all operational costs related to your business

-

At tax time, report an accurate breakdown of your business expenses

-

The key to any profitable business is keeping an accurate business plan, so make sure you're tacking your costs and revenues. It may not seem important at the time but this can save you a ton of money down the road.

Log Costs

Not necessarily related to the sawmill itself but it's also important to consider the cost of the logs you plan on milling.

If you're planning on milling trees from your own property, you should consider the longterm impacts to your property:

-

-

The cost of sawing down and hauling the logs (fuel and manpower)

-

The cost of landscaping and stump clearing (purchasing, renting or borrowing a stump grinder)

-

The environmental cost to your property, and what you have to pay to replant the trees, plus the many years you'll be taking care of them.

-

While it's often much cheaper to mill trees from your own property it's also important to consider the cost as a landowner and to the land itself.

You may also decide to purchase logs from elsewhere. If so, you should consider the price of these logs and what you intend to get out of them.

You can offset the cost of your logs by selling slabs or other desirable cuts of wood. Listen to the market demand and make sure you make a decent profit off the average job you intend to do.

To help reduce the cost of your logs, you can also consider acquiring cheap or free logs:

-

-

Offer to haul away logs from neighbors properties after a storm

-

Make connections in the tree care industry in your are and offer to haul away logs at your own expense

-

Check to see if there's a public disposal site for trees cut down by your local government

-

By doing the legwork and making these connections you may be able to net free or cheap logs for your own custom sawing projects.

Equipment and Space Costs

Other miscellaneous expenses include the cost of equipment required to haul logs and the storage space for both your sawmill and log pile.

Many rural landowners will already own a tractor and a storage shed or a barn so they may already have that covered but it's important to think about how much space your sawmill will take up. Many sawyers also build themselves a sawmill shed, but that task becomes much easier once you have your own portable sawmill.

Don't forget that whatever equipment you use to load your logs, be it an ATV with a log arch or a tractor with a grapple will need fuel too, so consider those costs. As long as you avoid idling your equipment though those costs should be kept to a minimum.

Join the Woodland Mills Community Facebook group. Search advice and insights from over 65,000 knowledgeable, supportive members.

- Pre-purchase considerations

- Sawmill set-up support

- Project inspiration photos and videos

- Community troubleshooting support